high quality impeller of slurry pump factory

Latest articles

In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreFor example.

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreSlurry pipe diameter.

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreSubmersible Slurry Pump

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreDetermine the nature of the material to be pumped

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreUsing rubber as a wear lining material means

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreIf you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read More>Vertical Slurry Pump

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read MoreIn AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read Morefactors-to-consider-when-choosing-a-slurry-pump

high quality impeller of slurry pump factory...

high quality impeller of slurry pump factory 【high quality impeller of slurry pump factory】

Read More

Popular articles

- Slurry Pump

- As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

- Slurry Pump Speed

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- If youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

- >Dredge Pump

Latest articles

-

These mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

-

The Company Adopts Advanced Computer Aided Engineering Software

-

The company uses advanced computer assistant engineering software to design products and technology, which makes our

-

If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

-

Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

-

The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

Links

- Tunnels and bridges

- The 7 degree button bit

- The significance of tunneling tools lies in their ability to offer flexibility, security, and scalability. They allow organizations to extend their network infrastructure, maintain privacy, and ensure data integrity even in less secure public networks. However, it's essential to remember that while tunneling can enhance security, it's not a panacea. Misconfigurations or vulnerabilities in the tunneling tool itself can pose security risks.

- In addition to durability, tunnel bench drilling bits are also designed for optimal performance. These bits are engineered to deliver precise and efficient drilling, allowing for faster progress on tunneling projects. The design of the bits ensures maximum penetration rates, reducing the time and effort required to complete drilling tasks.

- There are several methods used in FGD, but the most common are wet FGD, dry FGD, and semi-dry FGD. Wet FGD, the most widely used method, involves spraying the flue gas with a limestone-based slurry, where the sulfur dioxide reacts to form calcium sulfate. This process can remove up to 95% of the sulfur dioxide present in the gas.

- Auger bits are long, spiral-shaped bits that are designed for drilling deep holes in wood. These bits have a screw-like design that helps pull the bit through the material while drilling, making them ideal for tasks that require drilling holes in thick or dense wood.

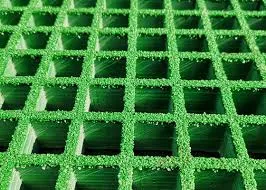

- The design flexibility of GRP allows for the creation of colorful and imaginative playground structures. These visually appealing designs capture children's attention and stimulate their imagination. From whimsical slides to intricate climbing frames, GRP can be molded into various shapes and sizes, providing a wide array of options for creative play. Such variety not only attracts children but also encourages them to engage in different types of activities, promoting physical fitness and motor skill development.

ballistic button bit. For individuals with limited motor control or those who use assistive devices, the ballistic system could be adapted to fit their needs, providing a more customizable and responsive alternative to conventional buttons.

ballistic button bit. For individuals with limited motor control or those who use assistive devices, the ballistic system could be adapted to fit their needs, providing a more customizable and responsive alternative to conventional buttons.Standards and Compliance

thread button bit. Its unique design enables it to maintain a cooler operating temperature, thereby reducing wear and tear and prolonging the bit's lifespan. This, in turn, reduces costs associated with frequent replacement and maintenance.

thread button bit. Its unique design enables it to maintain a cooler operating temperature, thereby reducing wear and tear and prolonging the bit's lifespan. This, in turn, reduces costs associated with frequent replacement and maintenance.